Vietnam Film Faced Plywood

| Size | 1220x2440mm, 1250x2500mm, 1500x3000mm, or as Customized(Max: 1830x3830mm) |

| Thickness | 9mm – 40mm |

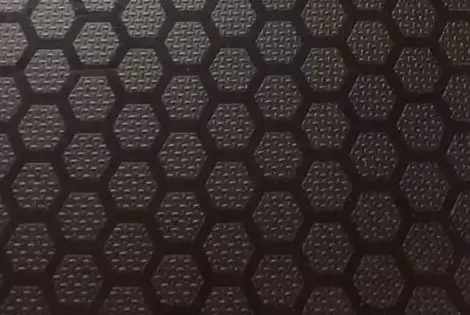

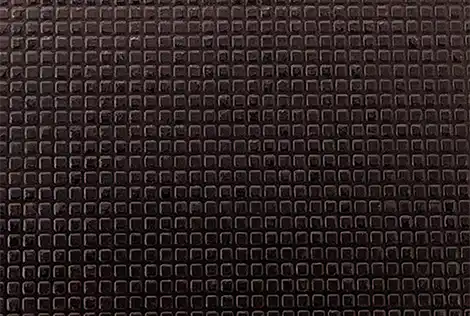

| Face / Back | Dark Brown Film, Black Film, Anti Slip Film |

| Core Material | Birch, Eucalytpus, Acacia, White Hardwood, Rubber, Combi,etc. |

| Glue Type | MR, WBP, Phenolic Dynea |

| Certification | ISO, FSC, CE, SGS, EUTR, CARB, EPA |

| Application | Construction, Formwork system, shuttering, etc |

What is Film Faced Plywood?

Film Faced Plywood is a high-performance construction plywood specifically engineered for concrete formwork and shuttering applications. Manufactured in Vietnam for export markets, this plywood features a phenolic film-coated surface that provides excellent resistance to moisture, abrasion, and concrete adhesion.

Designed to meet the expectations of European contractors and construction material distributors, Film Faced Plywood offers consistent panel strength, smooth concrete finish, and multiple reuse cycles, helping reduce overall project costs while maintaining structural reliability.

Plywood Core

We offer a wide range of professional-grade plywood cores, each designed to meet different performance and budget requirements.

Acacia Core Plywood is a high-strength hardwood plywood produced from premium Vietnamese Acacia. Known for its excellent density, superior load-bearing capacity, and long service life.

White Hardwood Core (often made from species like Bodhi or mixed light hardwoods) offers good stability and balanced mechanical strength. Provides a great cost-performance ratio, widely available, and versatile for many mid-range commercial applications.

Eucalyptus Core Plywood is engineered for projects requiring maximum strength, high compression resistance, and excellent bending performance. Produced from dense eucalyptus hardwood.

Combi Core Plywood combines multiple Vietnamese hardwoods—usually Eucalyptus + Acacia or Hardwood + Softwood—to offer a hybrid core that balances strength, weight, and cost-efficiency.

Dynea Film

Optional Film

Optional Glue

| Glue Type | Best For | Advantages |

|---|---|---|

| WBP Phenolic Glue | Bridges, tunnels, high-rise projects, heavy-duty formwork |

• Highest waterproof & heat resistance • Stable bonding under high pressure • Smooth concrete finish • Long lifespan |

| WBP Melamine Glue | Residential buildings, warehouses, civil works |

• Good balance of durability & cost • Suitable for repeated use • Popular for wholesale demand |

| MR Urea Glue | Temporary projects, dry condition formwork, low-budget jobs |

• Most economical • Suitable for single-use or short-term work |

Key Features & Benefits

- High Wear-Resistant Film Surface

The phenolic film protects the panel from water penetration and surface damage, ensuring a smooth finish after concrete pouring. - Strong & Stable Core Construction

Multi-layer hardwood or mixed-core structure delivers excellent load-bearing capacity and dimensional stability during use. - Multiple Reuse Capability

Suitable for repeated formwork cycles when properly handled, improving cost efficiency on construction sites. - Easy Demoulding & Clean Finish

Smooth film surface reduces concrete adhesion, minimizing surface defects and cleaning time. - Reliable Performance in Site Conditions

Designed to perform under varying European climate and job-site conditions.

Applications

Film Faced Plywood is widely used in European construction and infrastructure projects, including:

- Concrete formwork and shuttering systems

- Slab, column, beam, and wall formwork

- Commercial and residential building projects

- Infrastructure and civil engineering works

Its strength and surface durability make it suitable for both small-scale contractors and large construction projects.

Why Choose Film Faced Plywood from Vietnam?

Vietnam has become a trusted global supplier of construction plywood due to efficient manufacturing, stable raw material sourcing, and strong export experience. Film Faced Plywood produced in Vietnam offers European buyers a balanced solution between quality, consistency, and cost control.

Manufacturers are familiar with European documentation requirements and can support:

- Low-emission glue systems

- CE-related documentation upon request

- Stable lead times and bulk export capacity

FAQ

1. What are the main uses of Film Faced Plywood?

It is mainly used for concrete formwork, scaffolding platforms, bridge and road construction, truck flooring, industrial flooring, and heavy-duty packaging thanks to its strong surface and durability.Its stable bonding, uniform core, and cost efficiency make it ideal for large-scale commercial fit-outs and OEM furniture production.

2. Is Film Faced Plywood waterproof?

Yes. The phenolic film and waterproof glue (WBP, Melamine, or Phenolic) make it moisture-resistant. Edge sealing is recommended for longer service life.

3. What is the best thickness for commercial or construction projects?

- 12–15mm: General formwork

- 18mm: Heavy formwork and best overall choice

- 21mm+: Bridges and high-load platforms

Most B2B buyers choose 18mm for strength and value.

4. What determines the price of Film Faced Plywood?

Price depends on the core (Hardwood, Eucalyptus, Combi), glue type, film quality, thickness, grade, and market conditions. Phenolic glue hardwood panels offer the best cost-performance.

5. How many times can a single panel be reused?

This depends on the core wood, glue, and manufacturing process used in Film Faced Plywood.igh-grade film faced plywood can be reused up to 10–20 times in concrete pouring projects. Proper cleaning and storage between uses will extend its lifespan.

Other Film Faced Plywood

Contact Us for Free Samples

WhatsApp/Tel

+86 19953949496

dongstar@dongstar.com

Factory Site

Yen Bai Province, Vietnam