Anti-Slip Film Faced Plywood

| Size | 1220x2440mm, 1250x2500mm, 1500x3000mm, or as Customized(Max: 1830x3830mm) |

| Thickness | 9mm – 40mm |

| Face / Back | Anti-Slip Film |

| Core Material | Birch, Eucalytpus, Acacia, White Hardwood, Rubber, Combi,etc. |

| Glue Type | E0, E1, E2, MR, WBP, Phenolic Dynea |

| Certification | ISO, FSC, CE, SGS, EUTR, CARB, EPA |

| Application | Construction, Formwork system, shuttering, etc |

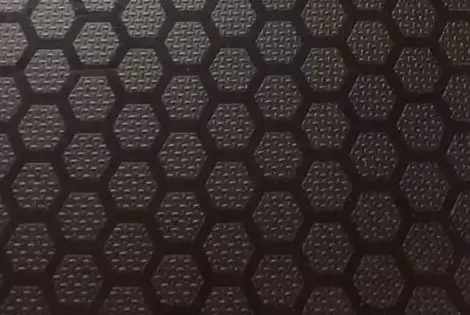

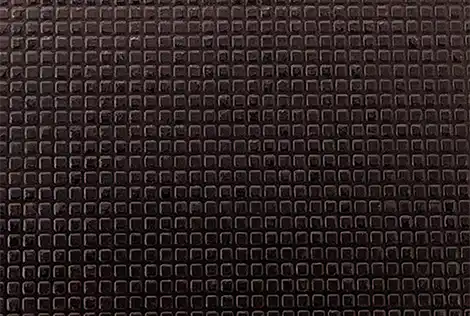

What is Wire Mesh Film Faced Plywood?

Wire Mesh Film Faced Plywood(also known as Anti-Slip Film Faced Plywood) is a specialized construction plywood designed for applications where surface grip and safety are critical. Manufactured in Vietnam for export to Europe, this plywood features a phenolic film with anti-slip patterning on one or both sides, providing enhanced traction in wet, dusty, or high-traffic environments.

Combining a strong multi-layer core with a wear-resistant non-slip surface, Anti-Slip Film Faced Plywood is widely used in formwork platforms, scaffolding decks, temporary flooring, and transport applications across European construction and industrial projects.

Anti-slip Film

Key Features & Advantages

- Anti-Slip Phenolic Film Surface

The patterned phenolic film improves grip and reduces slip risk, supporting safer working conditions on site. - High Moisture & Wear Resistance

The film surface protects against water, abrasion, and alkaline concrete exposure. - Strong Load-Bearing Performance

Engineered core construction ensures stability and strength under heavy loads and repeated use. - Extended Service Life

Designed for multiple reuse cycles when edges and surfaces are properly maintained. - Versatile Double- or Single-Sided Options

Available with anti-slip film on one side and smooth film on the reverse, or anti-slip on both sides.

Project Applications

1. Core Construction & Formwork: concrete formwork plywood, heavy-duty construction formwork, anti-slip formwork panel, high-rise construction shuttering.

2. Specific High-Risk Environments: slip resistant scaffolding boards, roofing walkboards, temporary flooring, safe access platforms.

3. Industrial & Infrastructure Projects: bridge deck construction, infrastructure project formwork, industrial concrete slab formwork.

FAQ

1. Is Wire Mesh Film Faced Plywood waterproof?

Yes. The phenolic film coating and sealed edges provide strong water and moisture resistance, ideal for outdoor and high-traffic environments.

2 How long does Anti-Slip Film Faced Plywood last?

With proper sealing and maintenance, it offers long service life thanks to its anti-slip film, strong bonding glue, and durable core structure.

3. What types of glue are used?

Most manufacturers offer WBP (Phenolic), Melamine, or E1/E0 glue options, depending on moisture exposure and project requirements.

4. How does Wire Mesh Film Faced Plywood differ from regular film faced plywood?

It features a textured hexagonal or wire-mesh surface that provides extra grip, making it safer for flooring and load-bearing surfaces.

5. Can it be used for outdoor commercial projects?

Absolutely. Its anti-slip surface, waterproof film, and strong edge sealing make it suitable for outdoor stages, ramps, platforms, and marine logistics.

6. What sizes are most common?

The standard size is 1220×2440mm, with customizable thicknesses from 9mm to 21mm for different load requirements.

Contact Us for Free Samples

WhatsApp/Tel

+86 19953949496

dongstar@dongstar.com

Factory Site

Yen Bai Province, Vietnam